Heating industrial processes

To aid the energy transition, companies can use our bio-carbon or integrate our torrefaction technology into their existing production plant. This for the purpose to heat furnaces in production processes.

Carbon sink and products

Bio-carbon can be a ready-to-use material for applications to create renewable products. Bio-carbon improves the product properties and at the same time preserves carbon atoms (carbon sink). Known applications are for instance composites in construction, soil improvement in agriculture and the (bio-)plastic industry (fillers and fibers).

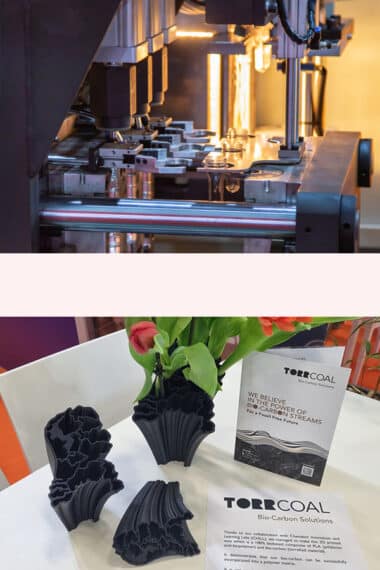

A promising example

Thanks to our collaboration with Chemelot Innovation and Learning Labs (CHILL), we managed to make this 3D printed vase which is a 100% biobased composite of PLA (polylactic acid biopolymer) and bio-carbon. It demonstrates that our bio-carbon can be incorporated successfully to a polymer matrix. It is yet another very promising example of a carbon sink application!

Raw material for chemical processes

Bio-carbon can provide sustainable carbon atoms as an alternative for fossil resources. Torrefaction enables the production of a highly homogeneous material of a constant quality, which is used as raw material for chemical processes, like bio-refinery, gasification and pyrolysis. In the steel industry it can also act as a fossil-free reducing agent.

About TorrCoal

We believe in the power of bio-carbon solutions. A clean and consistent way to charge your industrial installations. What if you could produce your own renewable carbon stream? What if you could use this as a cleaner carbon source in your existing fossil coal-based installations? Or as a more sustainable source of carbon atoms for steel production? Or as a fossil carbon replacement in general? Or as carbon sink? Now you can. With TorrCoal.

Projects

Knowledge

Contact us

Ghania Ounoughene

(R&D Engineer Innovation, Sustainability and Circular Economy)

Lode Smeets

(EPC- Director Rotary Equipment & Process )